Perkins 4 cylinder diesel engines are known for their reliability and durability. The Perkins 4.41 Series Workshop Manual is a comprehensive guide for servicing and overhauling these engines. It provides detailed instructions on everything from basic maintenance to complex repairs. The manual is available for download in PDF format, making it easy to access and use. You can also find a variety of other Perkins engine manuals online, including those for the 404C-22 and 404C-22T engines, the 900 Series CR 3 cylinder diesel engine, and the 1100 Series.

Introduction

Perkins engines are renowned for their robust construction, reliability, and fuel efficiency, making them a popular choice for various applications, including agriculture, construction, marine, and industrial settings. The company’s commitment to innovation and quality has resulted in a wide range of engine models, catering to diverse power requirements. Among their offerings, the Perkins 4-cylinder diesel engines have gained widespread recognition for their versatility and performance.

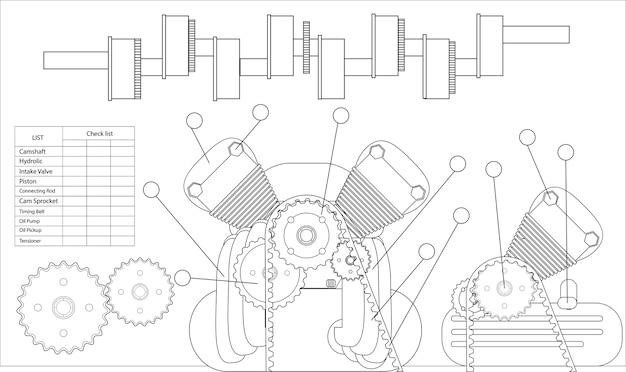

The Perkins 4-cylinder diesel engine manual PDFs serve as invaluable resources for anyone involved in the maintenance, repair, and operation of these engines. These manuals provide comprehensive information, detailed diagrams, and step-by-step instructions to ensure efficient and safe handling of the engines. Whether you’re a professional mechanic or a DIY enthusiast, these manuals offer the necessary guidance to keep your Perkins 4-cylinder engine running smoothly.

This article will delve into the importance and availability of Perkins 4-cylinder diesel engine manuals, exploring the benefits of having access to these resources. We will also discuss the various types of manuals available, covering topics such as workshop manuals, operation and maintenance manuals, and service and training manuals. Furthermore, we will highlight the key information contained within these manuals, emphasizing their role in ensuring optimal engine performance and longevity.

Perkins Engine History

The story of Perkins engines begins in 1932 with the establishment of Perkins Ltd. by Frank Perkins and Charles Wallace Chapman in Peterborough, England. The company’s initial focus was on developing and manufacturing agricultural machinery, but their true breakthrough came with the introduction of the 6.354 diesel engine in 1960. This marked a pivotal moment in Perkins’ history, solidifying their position as a leading manufacturer of diesel engines.

The 6.354 engine, known for its durability and reliability, quickly gained popularity in various sectors. This success led to the development of a diverse range of engine models, including the Perkins 4-cylinder diesel engines, which became a mainstay in applications ranging from agriculture and construction to marine and industrial settings. The company’s commitment to innovation and quality continued, resulting in numerous advancements in engine design, performance, and fuel efficiency.

Over the years, Perkins has expanded its global reach, establishing a network of distributors and service centers worldwide. This expansion has enabled them to provide comprehensive support to their customers, ensuring the availability of parts, service, and training for their engines. The company’s dedication to customer satisfaction has contributed to their enduring reputation as a trusted provider of diesel engines.

Perkins 4.41 Series Workshop Manual

The Perkins 4.41 Series Workshop Manual is a comprehensive guide designed to assist technicians in the servicing and overhaul of Perkins 4.41 engines. This manual provides detailed information and instructions covering a wide range of procedures, from routine maintenance tasks to complex repairs.

The 4.41 Series manual is organized in a logical and user-friendly manner, making it easy to locate the specific information you need. It includes detailed diagrams, illustrations, and step-by-step instructions to ensure clear understanding and accurate execution of procedures.

The manual covers various aspects of the 4.41 engine, including⁚

- Engine specifications and general information

- Disassembly and assembly procedures

- Component identification and function

- Troubleshooting and repair techniques

- Safety precautions and warnings

The Perkins 4.41 Series Workshop Manual is an essential resource for anyone involved in the maintenance and repair of these engines. It provides the necessary knowledge and guidance to ensure proper operation and extend the lifespan of the engine.

Perkins 404C-22 & 404C-22T Engines

The Perkins 404C-22 and 404C-22T engines are robust and reliable four-cylinder diesel engines designed for various applications, including agricultural and industrial machinery. These engines are known for their durability, fuel efficiency, and ease of maintenance.

The 404C-22 is a naturally aspirated engine, while the 404C-22T features a turbocharger for increased power output. Both engines are equipped with a robust cast-iron cylinder block and head, providing exceptional strength and longevity. The Perkins 404C-22 and 404C-22T engines are renowned for their ability to withstand demanding operating conditions and provide consistent performance.

The availability of comprehensive workshop manuals for these engines is a testament to their widespread use and the importance of proper maintenance. These manuals provide detailed instructions and technical information, enabling technicians to perform routine maintenance, diagnose problems, and carry out repairs efficiently and effectively. The Perkins 404C-22 and 404C-22T engines are reliable workhorses, and the comprehensive workshop manuals ensure they continue to operate at peak performance for years to come.

Perkins 900 Series CR 3 Cylinder Diesel Engine Service Repair Manual

The Perkins 900 Series CR 3 Cylinder Diesel Engine Service Repair Manual is a comprehensive guide for technicians working on these compact and powerful engines. This manual provides detailed instructions for servicing, overhauling, and troubleshooting these engines, ensuring optimal performance and longevity. The manual covers various aspects of engine maintenance, including engine disassembly and reassembly, component replacement, and troubleshooting common issues.

The Perkins 900 Series CR 3 Cylinder Diesel Engine Service Repair Manual is an essential tool for anyone involved in maintaining and repairing these engines. It provides detailed information on the engine’s design, operation, and maintenance procedures, ensuring technicians have the knowledge and guidance needed to perform tasks accurately and efficiently. The manual includes diagrams, illustrations, and step-by-step instructions to facilitate understanding and ensure correct procedures are followed.

The Perkins 900 Series CR 3 Cylinder Diesel Engine Service Repair Manual is an invaluable resource for technicians and anyone working on these engines. It provides comprehensive information on maintenance, repair, and troubleshooting, ensuring these engines remain reliable and perform optimally for years to come. With its detailed instructions, diagrams, and step-by-step procedures, the manual empowers technicians to confidently handle various maintenance and repair tasks, ensuring the long-term performance and reliability of these engines.

Perkins 1100 Series Workshop Manual

The Perkins 1100 Series Workshop Manual is a vital resource for technicians working on these robust and reliable four-cylinder diesel engines. This manual provides comprehensive guidance on servicing, overhauling, and troubleshooting the Perkins 1100 Series engines, ensuring their optimal performance and longevity. The manual covers a wide range of topics, including engine disassembly and reassembly, component replacement, and troubleshooting common issues, empowering technicians to confidently handle various maintenance and repair tasks.

The Perkins 1100 Series Workshop Manual is designed to provide technicians with the necessary information and instructions to perform tasks accurately and efficiently. It includes detailed diagrams, illustrations, and step-by-step procedures, making it easy to understand and follow. The manual covers various models within the 1100 Series, ensuring technicians have access to the specific information they need for each engine variant.

This comprehensive manual is an indispensable resource for anyone working on Perkins 1100 Series engines. It provides clear and concise instructions, ensuring technicians can maintain and repair these engines effectively. The manual’s detailed information and step-by-step procedures promote accurate and efficient work, ensuring the long-term performance and reliability of these powerful and dependable engines. The Perkins 1100 Series Workshop Manual is a valuable tool for technicians, allowing them to confidently handle various maintenance and repair tasks, ensuring the engines operate optimally for years to come.

Perkins 700 Series UB Four Cylinder Diesel Engine Service Repair Manual

The Perkins 700 Series UB Four Cylinder Diesel Engine Service Repair Manual is a comprehensive guide for technicians working on these robust and reliable engines. This manual provides detailed instructions and information on servicing, overhauling, and troubleshooting the Perkins 700 Series UB engines, ensuring their optimal performance and longevity. The manual covers a wide range of topics, including engine disassembly and reassembly, component replacement, and troubleshooting common issues, empowering technicians to handle various maintenance and repair tasks with confidence.

The Perkins 700 Series UB Service Repair Manual is designed to provide technicians with the necessary information and instructions to perform tasks accurately and efficiently. It includes detailed diagrams, illustrations, and step-by-step procedures, making it easy to understand and follow. The manual covers various models within the 700 Series UB, ensuring technicians have access to the specific information they need for each engine variant.

This comprehensive manual is an indispensable resource for anyone working on Perkins 700 Series UB engines. It provides clear and concise instructions, ensuring technicians can maintain and repair these engines effectively. The manual’s detailed information and step-by-step procedures promote accurate and efficient work, ensuring the long-term performance and reliability of these powerful and dependable engines. The Perkins 700 Series UB Service Repair Manual is a valuable tool for technicians, allowing them to confidently handle various maintenance and repair tasks, ensuring the engines operate optimally for years to come.

Perkins 403C-11, 403C-15, 404C-22, and 404C-22T Workshop Manual

The Perkins 403C-11, 403C-15, 404C-22, and 404C-22T Workshop Manual is a comprehensive guide designed to assist technicians in servicing and overhauling these popular Perkins 4-cylinder diesel engines. It covers a wide range of topics, from routine maintenance procedures to complex repair tasks, ensuring technicians have the information they need to keep these engines running smoothly. This manual is an invaluable resource for technicians working on these Perkins engines, providing detailed instructions, diagrams, and specifications to facilitate accurate and efficient work.

The manual includes detailed information on engine components, including the cylinder head assembly, piston and connecting rod assemblies, and fuel system. It also covers the operation and maintenance of various engine systems, such as the cooling system, lubrication system, and electrical system. With its clear and concise language, along with numerous illustrations and diagrams, this manual makes it easy to understand and follow the procedures for servicing and overhauling these Perkins engines.

The Perkins 403C-11, 403C-15, 404C-22, and 404C-22T Workshop Manual is an essential resource for technicians who want to ensure the optimal performance and longevity of these reliable engines. It provides the necessary information and instructions for performing various tasks, from routine maintenance to complex repairs, allowing technicians to confidently handle any challenges they may encounter.

Perkins Engine Operation and Maintenance Manuals (OMMs)

Perkins Engine Operation and Maintenance Manuals (OMMs) are essential resources for owners and operators of Perkins engines, providing comprehensive information on the proper operation, maintenance, and troubleshooting of these engines. These manuals are designed to ensure that owners and operators can keep their Perkins engines running efficiently and reliably for years to come. They cover a wide range of topics, from routine maintenance procedures to detailed instructions on diagnosing and resolving common engine issues.

Perkins OMMs are available for a wide range of Perkins engines, including the popular 4-cylinder diesel models. These manuals provide clear and concise instructions on various aspects of engine operation and maintenance, such as engine starting and stopping procedures, checking fluid levels, changing oil and filters, and performing routine inspections. They also include detailed information on engine performance, fuel consumption, and emissions.

In addition to providing detailed instructions, Perkins OMMs also include helpful diagrams, illustrations, and troubleshooting charts. These resources make it easier for owners and operators to understand the information presented and to identify and resolve potential problems. Perkins OMMs are an invaluable resource for anyone who owns or operates a Perkins engine, providing the necessary information and guidance to ensure optimal performance and longevity.

Perkins Engine Number Location

The Perkins engine number is a crucial piece of information for identifying your specific engine and obtaining the right parts, service, and support. This unique identifier helps to ensure that you receive the correct components and assistance for your engine. The engine number is typically found on the cylinder block, a prominent part of the engine that houses the cylinders where combustion takes place. This location makes it relatively easy to access and identify the engine number for reference.

To locate the engine number, look for a metal tag or plate attached to the cylinder block. The tag or plate will usually have the engine number stamped or embossed on it. In some cases, the engine number may be directly cast into the cylinder block. If you have difficulty finding the engine number, consult your Perkins engine operation and maintenance manual or contact your local Perkins dealer for assistance.

Once you have located the engine number, make sure to record it accurately. This will allow you to easily provide it to Perkins or their authorized dealers when requesting parts, service, or technical support. Knowing your engine number is essential for ensuring proper maintenance and repair, maximizing the lifespan of your Perkins engine, and obtaining the right service for your specific engine model.

Perkins Engine Service and Training

Perkins recognizes the importance of proper engine maintenance and service for ensuring optimal performance and longevity. To support their customers, Perkins offers a comprehensive range of service and training programs. These programs are designed to empower users with the knowledge and skills necessary to maintain and operate their Perkins engines effectively.

Service programs encompass a variety of options, including routine maintenance, troubleshooting, and repair services. Perkins has a global network of authorized dealers and service centers, providing convenient access to skilled technicians and specialized equipment for all your engine needs. These service centers are equipped to handle everything from basic oil changes and filter replacements to more complex repairs and engine overhauls.

Perkins also offers training programs for individuals and organizations involved in operating and maintaining their engines. These programs are tailored to different levels of expertise, ranging from introductory courses for beginners to advanced training for experienced technicians. Participants receive comprehensive instruction on engine operation, maintenance procedures, troubleshooting techniques, and safety protocols. These programs are designed to equip individuals with the knowledge and skills necessary to operate and maintain their Perkins engines effectively.

Perkins Engine Applications

Perkins 4-cylinder diesel engines have earned a reputation for their versatility and reliability, making them suitable for a wide range of applications across various industries. Their robust construction, efficient performance, and compact design have made them a popular choice for powering equipment in agriculture, construction, industrial, and marine sectors.

In agriculture, Perkins engines power a wide array of machinery, including tractors, combines, balers, and other farm equipment. Their ability to deliver reliable power under demanding conditions makes them ideal for the rigorous tasks involved in modern agriculture.

Construction equipment, such as excavators, loaders, and bulldozers, often rely on Perkins engines for their power and durability. These engines can withstand the heavy loads and demanding operating conditions encountered in construction projects.

Perkins engines also find extensive use in industrial applications, powering generators, pumps, compressors, and other machinery used in manufacturing, mining, and other industries. Their reliability and efficiency make them a suitable choice for powering critical equipment in demanding industrial environments.

In the marine sector, Perkins engines are commonly used in boats, yachts, and other watercraft. Their compact design, low emissions, and quiet operation make them ideal for recreational and commercial marine applications.