Dock Plate Hold-Down Assembly Removal Instructions

This guide outlines the steps for removing a dock plate hold-down assembly. The hold-down mechanism is crucial for securing the dock plate and ensuring a safe transition between the warehouse floor and the truck bed. Proper removal is essential for maintenance, repairs, or upgrades.

Safety Precautions

Before attempting any work on the dock plate hold-down assembly, prioritize safety by taking the following precautions⁚

- Disable Power⁚ Ensure the dock leveler is disconnected from any power source. This is crucial to prevent accidental activation and potential injuries.

- Clear the Area⁚ Remove any obstacles or personnel from the immediate vicinity of the dock leveler. This includes ensuring no one is underneath the dock plate or within the path of its movement.

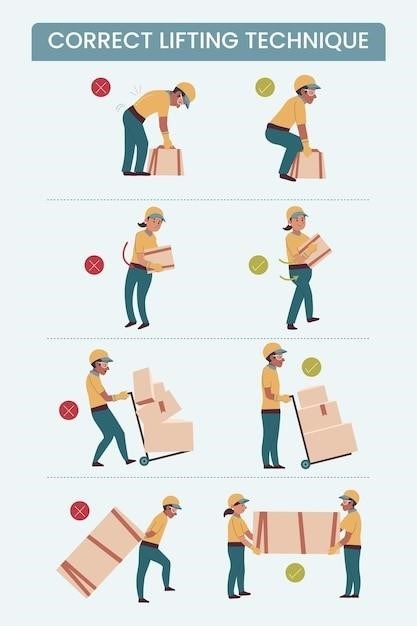

- Use Proper Lifting Equipment⁚ If heavy lifting is involved, utilize appropriate lifting equipment, such as a crane, hoist, or forklift. Ensure the equipment is rated for the weight of the assembly.

- Wear Protective Gear⁚ Wear appropriate personal protective equipment (PPE), including safety glasses, gloves, and sturdy footwear. This will help protect you from potential hazards during the removal process.

- Use Caution with Sharp Edges⁚ Be mindful of sharp edges on the hold-down assembly and other components. Handle them with care to avoid cuts or injuries.

- Be Aware of Falling Objects⁚ When working above the dock leveler, be mindful of potential falling objects. Secure any loose parts or tools to prevent accidents.

- Consult with Professionals⁚ If you are unsure about any part of the removal process or have concerns about safety, consult with qualified professionals for guidance.

By following these safety precautions, you can minimize the risk of accidents and ensure a safe working environment.

Equipment Needed

To safely and effectively remove the dock plate hold-down assembly, you will need the following equipment⁚

- Wrench Set⁚ A comprehensive set of wrenches, including both metric and standard sizes, will be necessary to loosen and tighten bolts and nuts during the removal process.

- Screwdriver Set⁚ A set of screwdrivers, including both Phillips and flathead types, is essential for removing screws that may be holding the assembly in place.

- Needle-Nose Pliers⁚ These pliers are useful for gripping and manipulating small parts, such as cotter pins or release clips, during the removal process.

- Safety Glasses⁚ Protect your eyes from flying debris or particles that may occur during removal.

- Gloves⁚ Wearing gloves will provide protection for your hands from sharp edges or potential contact with grease or oil.

- Lifting Equipment (Optional)⁚ Depending on the weight and design of the hold-down assembly, you may require lifting equipment such as a crane, hoist, or forklift to assist in removal.

- Maintenance Strut (Optional)⁚ If the dock leveler is being raised for removal, a maintenance strut will be needed to support the deck assembly while it is raised.

- Traffic Barriers (Optional)⁚ Use traffic barriers to create a safe work zone around the dock leveler, preventing accidental entry during the removal process.

- Replacement Parts (Optional)⁚ If the hold-down assembly is being replaced, ensure you have the correct replacement parts available before beginning the removal process.

Having all the necessary equipment on hand will make the removal process smoother and safer.

Disconnecting the Hold-Down Assembly

Disconnecting the hold-down assembly is the first step in removing it. This process involves releasing the mechanism that holds the dock plate in place, allowing it to move freely. The specific steps may vary depending on the type of hold-down assembly, but generally involve the following⁚

- Locate the Release Mechanism⁚ The release mechanism is usually a pull chain or a lever that releases the tension on the hold-down system. It may be located on the side, front, or rear of the dock leveler.

- Engage the Release Mechanism⁚ Pull the release chain or lever to release the hold-down mechanism. This will allow the dock plate to be raised or lowered freely.

- Check for Release⁚ After engaging the release mechanism, test the movement of the dock plate to ensure it is no longer held in place by the hold-down assembly. If the dock plate moves freely, you can proceed to the next step.

It is important to exercise caution during this step, ensuring that the dock leveler is properly supported and that no one is under or near the moving dock plate.

Removing the Hold-Down Assembly

Once the hold-down assembly is disconnected, it can be removed from the dock leveler. This process may involve several steps, depending on the specific design of the assembly. Here are some general guidelines for removing the hold-down assembly⁚

- Identify the Attachment Points⁚ The hold-down assembly is typically secured to the dock leveler using bolts, nuts, or other fasteners. Locate these attachment points and identify the type of fasteners used.

- Remove the Fasteners⁚ Using appropriate tools, carefully remove the fasteners that hold the hold-down assembly in place. Work slowly and methodically to avoid damaging any components.

- Disconnect any Cables or Wires⁚ If there are any cables or wires connected to the hold-down assembly, carefully disconnect them. Make sure to label the wires for easy reconnection during reinstallation.

- Lift and Remove⁚ Once all fasteners are removed, carefully lift and remove the hold-down assembly from the dock leveler. It is essential to have adequate support and assistance to avoid dropping or damaging the assembly.

Once the hold-down assembly is removed, it can be inspected, repaired, or replaced as needed.

Releasing the Hold-Down Mechanism

Releasing the hold-down mechanism is a critical step in removing the assembly. It allows the dock plate to lower safely and prevents damage to the mechanism or the dock leveler. The specific process for releasing the hold-down mechanism varies depending on the design, but here are some general steps⁚

- Locate the Release Mechanism⁚ The hold-down mechanism often has a release lever, handle, or pull chain. Locate this release mechanism, which is typically positioned near the hold-down assembly or on the dock leveler frame.

- Engage the Release Mechanism⁚ Follow the instructions provided in the dock leveler’s manual or by the manufacturer to properly engage the release mechanism. This might involve pulling a chain, rotating a lever, or pressing a button.

- Observe the Release⁚ As you engage the release mechanism, carefully observe the hold-down assembly. The dock plate should begin to lower as the mechanism releases the tension.

- Confirm Full Release⁚ Once the dock plate has lowered to its fully extended position, ensure the hold-down mechanism is completely released. This prevents the mechanism from accidentally engaging and causing damage during the removal process.

Once the hold-down mechanism is fully released, the dock plate is free to move and the assembly can be safely removed.

Removing the Hold-Down Bracket

The hold-down bracket, also known as the hold-down strap or anchor bracket, is the component that secures the hold-down assembly to the dock leveler or the surrounding structure. Removing the bracket is necessary to fully detach the assembly. Here’s a step-by-step guide⁚

- Identify the Fasteners⁚ The hold-down bracket is typically attached using bolts, nuts, or welds. Carefully inspect the bracket to identify the type of fasteners used.

- Prepare Tools⁚ Gather the necessary tools based on the type of fasteners. You’ll likely need wrenches, sockets, a breaker bar, or a grinder for cutting welds.

- Loosen and Remove Fasteners⁚ Using the appropriate tools, carefully loosen and remove the fasteners that hold the bracket in place. Be sure to work slowly and avoid applying excessive force to prevent damage.

- Disconnect the Bracket⁚ Once the fasteners are removed, gently detach the bracket from the dock leveler or surrounding structure. If the bracket is welded, you’ll need to use a grinder to cut the welds.

- Inspect the Attachment Points⁚ After removing the bracket, examine the attachment points on the dock leveler or structure for any signs of damage or wear. Repair or replace any damaged components before reinstalling the assembly.

After successfully removing the hold-down bracket, the hold-down assembly can be fully removed from the dock leveler.

Inspecting the Hold-Down Assembly

After removing the hold-down assembly from the dock leveler, a thorough inspection is crucial to ensure its functionality and identify any potential issues. This inspection will determine if the assembly needs repair, replacement, or can be reinstalled.

- Visual Inspection⁚ Begin by visually inspecting the entire assembly, including the ratchet bar, pawls, springs, and any other components. Look for signs of damage, wear, corrosion, or misalignment. Note any cracks, dents, broken parts, or excessive rust.

- Ratchet Bar Inspection⁚ Examine the ratchet bar for wear and tear on the teeth. Check if the teeth are worn down or damaged, as this can affect the hold-down’s ability to securely engage with the pawls.

- Pawl Inspection⁚ Inspect the pawls for wear and tear on the contact surfaces. Ensure the pawls are not bent, broken, or excessively worn. Damaged pawls can lead to slippage or failure of the hold-down mechanism.

- Spring Inspection⁚ Check the springs for proper tension and signs of fatigue. Ensure the springs are not broken, stretched, or weakened. Damaged springs can affect the hold-down’s ability to lift and secure the dock plate.

- Cable Inspection⁚ If the hold-down assembly uses a cable, inspect it for fraying, damage, or corrosion. Ensure the cable is securely attached to the assembly and that its movement is smooth.

- Lubrication⁚ Check the lubrication of the moving parts. Ensure the components are properly lubricated to prevent friction and wear. Apply a light coating of grease to any moving parts as needed.

If any issues are found during the inspection, the hold-down assembly may need to be repaired or replaced. Consulting a professional dock leveler technician is recommended for complex repairs or replacements.

Reinstalling the Hold-Down Assembly (Optional)

If the hold-down assembly was removed for inspection and deemed functional, it can be reinstalled. This step is optional, as the assembly may have been removed for other purposes, such as maintenance or replacement.

- Prepare the Assembly⁚ Ensure the hold-down assembly is clean and free of debris. Lubricate the moving parts, including the ratchet bar, pawls, and springs, with a light coating of grease to minimize friction and wear.

- Position the Assembly⁚ Carefully position the hold-down assembly back into its original location on the dock leveler; Ensure it is properly aligned with the mounting points and that all components are in their correct positions.

- Secure the Assembly⁚ Secure the hold-down assembly using the original mounting hardware. Tighten all bolts and nuts to the manufacturer’s specifications to ensure a secure and stable installation.

- Connect the Release Mechanism⁚ If applicable, reconnect the release mechanism (e.g., pull chain or cable) to the hold-down assembly. Ensure it is securely connected and operates smoothly.

- Test the Assembly⁚ After reinstalling the assembly, test its functionality. Operate the dock leveler through several cycles, lifting and lowering the dock plate to ensure the hold-down mechanism engages properly.

- Inspect for Issues⁚ After testing, inspect for any issues, such as slippage, misalignment, or unusual noises. If any problems are found, re-check the installation and address the issue before using the dock leveler.

Remember to consult the manufacturer’s instructions for specific details on reinstalling the hold-down assembly for your particular model. If you encounter any difficulties or have concerns about the installation process, it’s best to seek assistance from a professional dock leveler technician.

Testing the Hold-Down Assembly

After completing the installation or repair of the hold-down assembly, it’s crucial to thoroughly test its functionality to ensure it operates correctly and securely. This step is vital for guaranteeing the safe and reliable operation of the dock leveler.

- Safety First⁚ Before commencing any testing, ensure the work area is clear of any obstructions or personnel. It’s important to maintain a safe distance from the dock leveler during testing.

- Activate the Release Mechanism⁚ Activate the release mechanism (e.g., pull chain or cable) to disengage the hold-down assembly. This will allow the dock plate to rise.

- Raise and Lower the Dock Plate⁚ Operate the dock leveler by raising the dock plate to its full height. Then, slowly lower the dock plate back to its resting position.

- Check for Smooth Operation⁚ During the testing, observe the movement of the dock plate. It should move smoothly and without any jerky or sudden movements. Listen for any unusual noises or grinding sounds that may indicate a problem.

- Engage and Disengage the Hold-Down⁚ As the dock plate is raised and lowered, check that the hold-down assembly engages and disengages properly. The mechanism should securely lock the dock plate in position when lowered and release smoothly when activated.

- Multiple Cycles⁚ Perform several cycles of raising and lowering the dock plate to ensure consistent and reliable performance of the hold-down assembly. This will help identify any potential problems that may not be apparent during a single cycle.

If any issues or concerns arise during testing, stop the operation and investigate the problem. Address any malfunctions or inconsistencies before using the dock leveler for actual loading or unloading operations;